Intelligent Defect Detection and Process Optimization in Manufacturing

A worldwide manufacturing corporation sought to modernize its great manage and production line analytics the usage AI. Their traditional inspection systems couldn’t scale across multiple facilities or adapt to product variations.

The Challenge

Complexities We Had to Tackle

- Manual quality inspection limited throughput and consistency.

- Lack of visibility into process inefficiencies and root causes of defects.

- Data from IoT sensors and PLC systems remained siloed hindering holistic insights.

The Solution

Turning Challenges into Capabilities

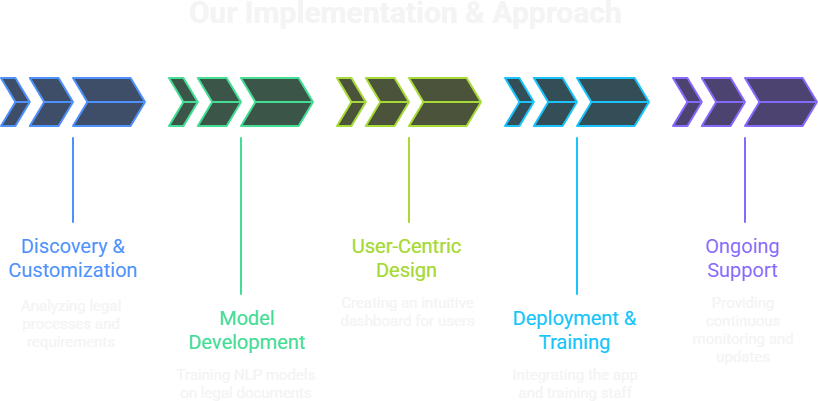

Cognoverse deployed an AI-driven production analytics machine integrating computer imaginative and prescient for illness detection and an ML-based system optimization.

Key Features:

- Visual Inspection AI: Deep learning to get to know fashions trained on high-resolution product imagery to locate micro-defects in real time.

- Production Line Analytics: Correlation models linking machine telemetry with illness rates to pick out technique bottlenecks.

- Centralized Dashboard: Real-time KPIs defect heatmaps and production performance analytics.

- Edge Deployment: On-premise AI inference for low-latency defect detection.

Impact

By integrating computer vision and process analytics, the manufacturer achieved real-time quality assurance, predictive process control, and higher production efficiency across global facilities.

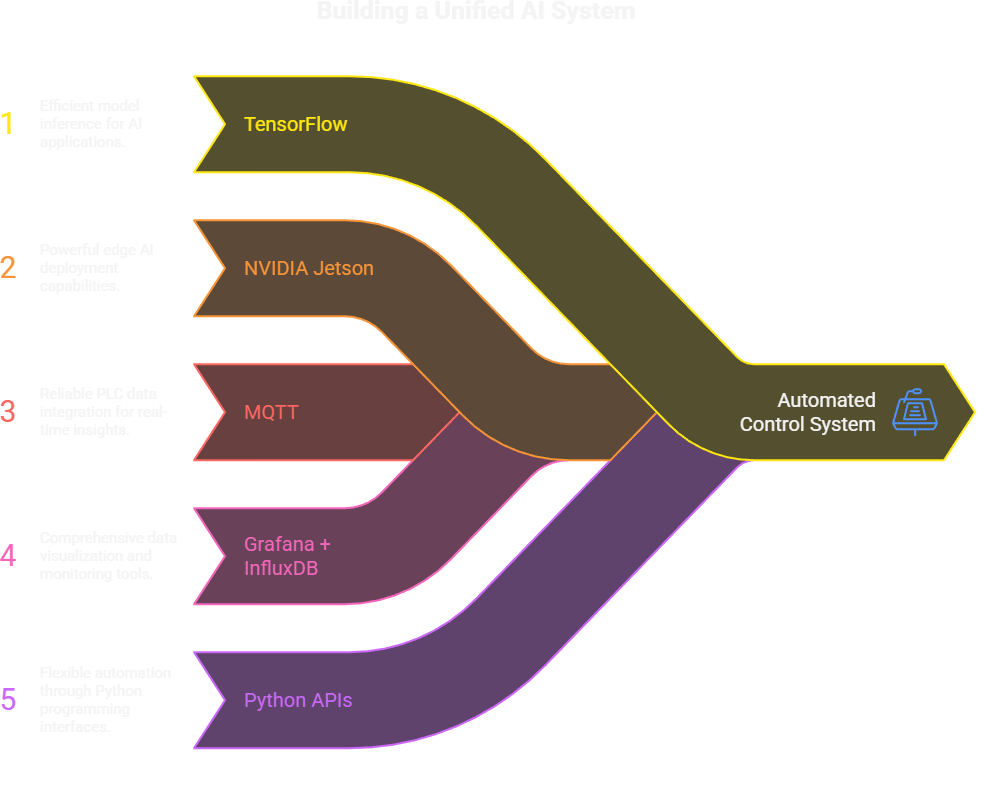

Technology Stack

- TensorFlow, ONNX Runtime for model inference

- Edge AI deployment using NVIDIA Jetson

- PLC data integration via MQTT

- Grafana + InfluxDB dashboards

- Python APIs for control system automation